Concrete Class And Concrete Group Correlation

Concrete Class And Concrete Group Correlation

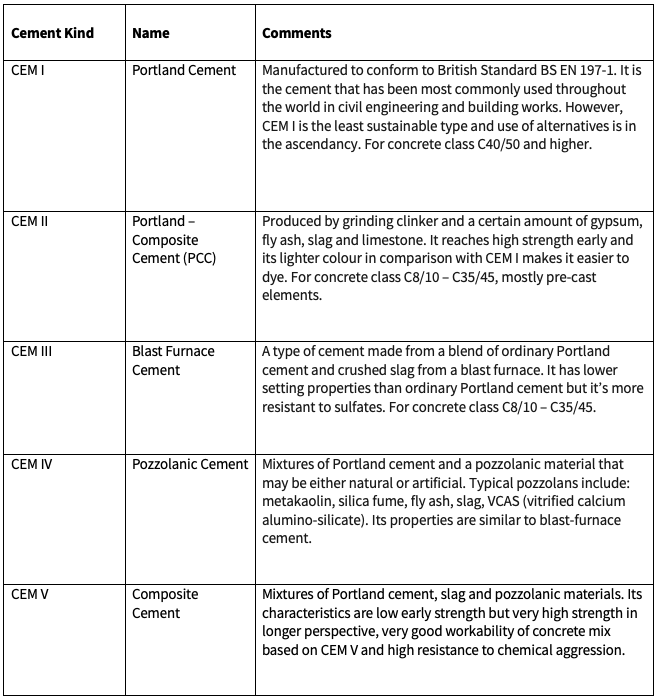

To better understand concrete groupings according to CIRIA R108 (1-7) it is important to recognise how different kinds of cement and admixtures influence this classification.

There are five kinds of cement (CEM I, II, III, IV and V) according to standard strength which are grouped into three classes: class 32.5, class 42.5 and class 52.5 (compressive resistance in MPa).

There are also three classes of early strength:

- N – class with ordinary early strength

- R – class with high early strength

- L – class with low early strength.

The latter can be applied only to CEM III cements. See the below table for further clarification:

[Letters A, B, C (e.g. CEM IIIA etc.) define slag content (A – lowest, C – highest)]

Cement, depending on its kind, class and presence of admixtures will also have a different heat of hydration reactions as well as resistance to sulfates or alkalinity. This means that cement options are vast, and when deciding what kind and class of cement should be implemented in a concrete mix production, the following characteristics have to be taken into consideration:

- What class (strength) of concrete is required?

- What are the environmental conditions (exposure class)?

- How long will it take to transport the concrete mix to site?

- What will be the method of concrete compaction?

- What will be the curing time and conditions?

Concrete class is defined by a structural engineer, whilst concrete mix characteristics depend on the type of construction, placing, compaction technique and transport time. When designing the composition of a concrete mix, the above must be taken into consideration so that the final result is optimal from both economical and technological points of view.

Concrete Type Depending On Application

BS 8500-1:2006, a complementary British Standard to BS EN 206-1, defines the specification, production and conformity of fresh concrete. In this document one can learn about parameters which concrete should have at different exposure classes (Table A.8) or what designated concrete (its min. strength class, max w/c ratio, cement and combination types) is required for different applications (Table A.31).

-TABLES MISSING-

Concrete Group Criteria

When looking at the table of guidance on concrete groupings for CIRIA R108 formwork pressure calculations, we can see that the concrete group depends on the type of cement implemented and the presence of retarding admixtures. The latter prolongs the process of hydration reaction in its initial period and slows down the rate of heat release. Retarding admixtures extends the transition time of concrete mix from plastic to rigid state. When using retarding admixtures initial concrete strength may be lower when compared to concrete without admixtures, whereas the final strength is normally higher. Retardants are usually added during the process of preparing the concrete mix, normally with mixing water. In some cases, however, it may be necessary to add a retarding admixture to a ready concrete mix e.g. in case of prolonged transport caused by failure or a traffic jam. The use of retarding admixtures is necessary when a need of long-distance transport occurs and for works carried out in conditions of high ambient temperatures.

Concrete Class and Group Correlation Conclusion

Concrete mix design depends on many variables. To design it efficiently one must know the requirements for concrete strength, durability, application, means of transport, compacting methods on site and details of RC elements. Based on this information the cement type, w/c ratio, thermal requirements and necessity of introducing admixtures etc. can be determined. There is no direct correlation between the concrete class (strength) and the concrete group. It is impossible to derive what group concrete belongs to based just on its strength. To be able to classify concrete mix to a certain group, one must seek additional information, particularly the exact cement type and presence of any retarding admixtures.

Read more Technical Guidelines.