Formwork Design

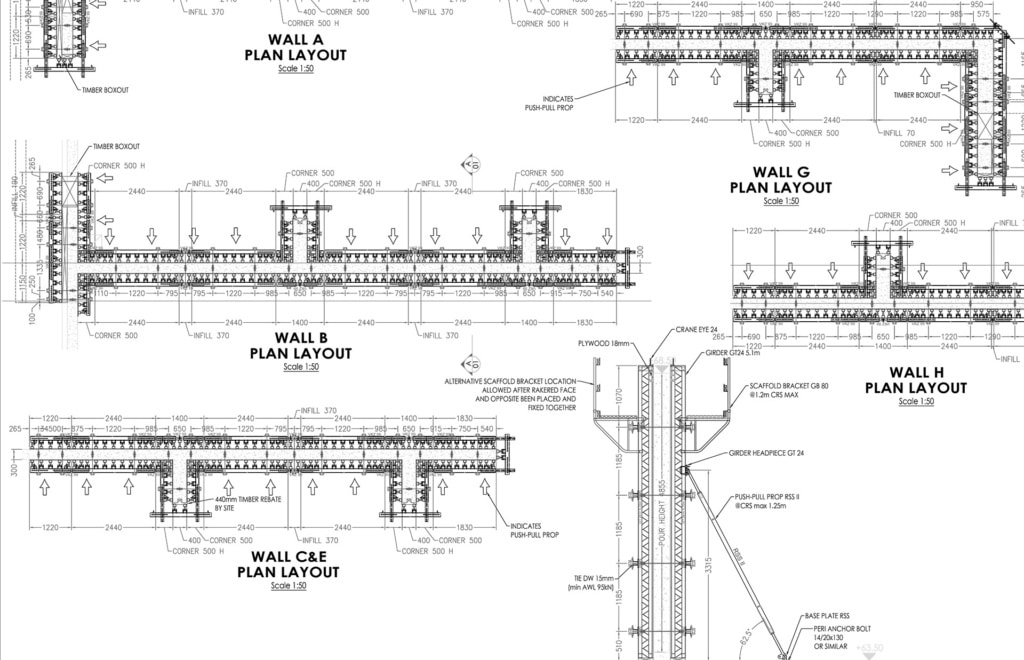

Using elements of mechanical and structural engineering principles, formwork design requires the necessary engineering expertise to carry out the required calculation, specify the materials and provide the dimensions of the formwork to enable the required accuracy of the design, taking into account the requirements of varying temperature, dead load and vibration of the wet concrete.

We work to the latest codes of practice including British Standards and Eurocodes, as well as industry guidance, and are committed to designing out risk.

WE OFFER

- Site Meetings, Inspections and Surveys

- Detailed Design Drawings and Calculations

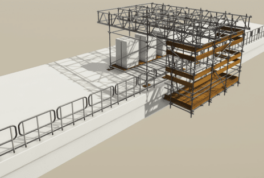

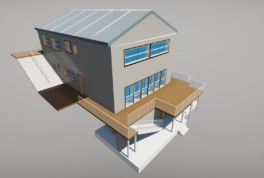

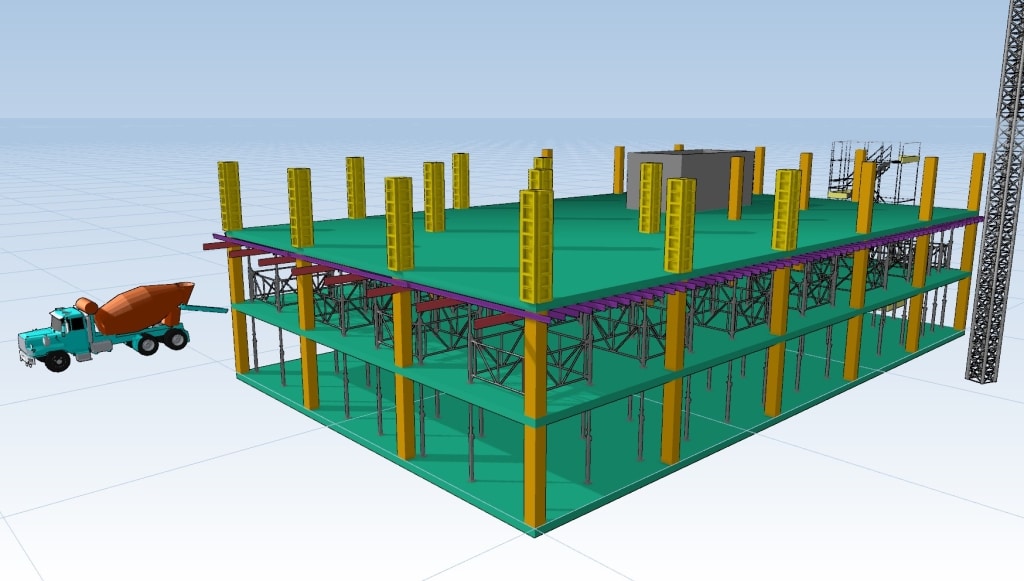

- 3D Design with Automated Equipment Scheduling

- Feature Finishes

- Backpropping Analysis

- Falsework Design

- Material Scheduling and Quantities

- Phasing and Early Striking Time Analysis

- Concrete Pressure and Allowable Rate of Rise Calculation

- Core Stability Analysis

- Screen Design

Formwork Design is the process of specifying the configuration necessary to enable the formwork to be manufactured and easily assembled and disassembled, whilst maintaining the strength to withstand the hydrostatic forces exerted by the wet concrete.

Formwork is needed by all contractors who are responsible for the construction of concrete structures, be they walls, columns or foundations, on a construction site or any other project. The importance of formwork cannot be overstressed as it is directly responsible for the final appearance, accuracy and integrity of the finished, hardened concrete structure.

Regulations are contained within an approved official ‘standard’ which, in the UK, is BS5975:2019 (published by the BSI). These enable the designer, detailer and contractors to ensure that the design carried out will meet the requirements of the standard, not least, regarding the formwork having proper constructability so that it’s safe to use. We work to the latest codes of practice including British Standards and Eurocodes, as well as industry guidance.

We know how expensive hiring a completely new set of new equipment is, and, as an independent company we always endeavour to utilise customer-owned equipment and materials and re-sequence its use within the overall scheme where possible. We are happy to take direction on phasing and preferred equipment in every project.

Get in touch to discuss your design requirements.

We also undertake all other forms of temporary works design including scaffold and access, as well as design and detailing of structural steel and connections and reinforcement detailing.